The Ultimate Guide to Pallet Handling Robots: Types, Benefits, and How They Work

Date:2026-01-28

The relentless movement of pallets forms the backbone of global logistics, manufacturing, and warehousing. For decades, this task relied on manual labor and forklifts—methods prone to fatigue, inconsistency, high costs, and safety incidents. Today, a silent revolution is automating these critical workflows: the pallet handling robot.

These intelligent machines are transforming stagnant storage areas into dynamic, efficient, and data-driven hubs. But what exactly are they, and how can they fit into your operation? This comprehensive guide will explain the technology behind pallet handling robots, explore the different types available, detail their tangible benefits, and provide a roadmap for successful integration.

What is a Pallet Handling Robot and How Does It Work?

A pallet handling robot is an automated mobile machine designed to transport, load, unload, or stack palletized goods without the need for a human operator on the vehicle. It’s more than just a motorized pallet jack; it’s a sophisticated system that perceives its environment, makes intelligent decisions, and executes tasks with precision.

The functionality hinges on a powerful integration of hardware and software:

-

Navigation & Perception (The "Eyes and Brain"): This is the core of autonomy. Most modern robots, especially Autonomous Mobile Robots (AMRs), use SLAM (Simultaneous Localization and Mapping) technology. As the robot moves, it uses sensors like LiDAR and cameras to build a map of its environment while simultaneously tracking its own location within it. Advanced systems, like the laser SLAM+ visual SLAM fusion mentioned in industry profiles, offer superior accuracy and reliability, particularly in dynamic spaces where people and other equipment move freely.

-

Chassis & Drive System (The "Legs"): Engineered for warehouse environments, it provides stable and efficient mobility across concrete floors, over minor cracks, and sometimes even between facilities.

-

Lift Mechanism (The "Arms"): This is the interface with the load. It can be a set of forks (like a traditional forklift), a conveyor deck, or a specialized clamp, designed to engage, lift, and secure standard pallets or custom containers.

-

Fleet Management Software (The "Conductor"): This is the cloud-based or on-premise command center. It’s where the true power of automation multiplies. This software assigns tasks, optimizes traffic in real-time to prevent congestion, manages battery charging, and integrates with your Warehouse Management System (WMS). A robust system, as noted in competitive analyses, can coordinate multi-robot workflows to boost overall operational efficiency by 40% or more.

Types of Pallet Handling Robots: AMRs, AGVs, and Beyond

Not all pallet handling robots are created equal. Choosing the right type depends on your facility's layout, process variability, and long-term goals. The table below breaks down the primary categories.

| Feature | Autonomous Mobile Robot (AMR) | Automated Guided Vehicle (AGV) | Robotic Forklift / Unmanned Forklift AGV |

| Navigation | |||

| Best For | Dynamic environments, mixed human-robot workflows, facilities with frequent layout changes. | Repetitive, high-volume point-to-point moves in stable environments with minimal obstruction. | Direct replacement of manual forklift tasks, especially for high stacking (>10 ft) and heavy loads (>2,000 kg). |

| Flexibility | |||

| Upfront Cost | Typically higher due to advanced sensors and software. | Often lower for simple implementations. | High, comparable to or exceeding advanced AMRs, due to heavy-duty mechanics. |

| Key Advantage | Adaptability and intelligence in complex, changing spaces. | Predictability and high reliability for simple, repetitive tasks. | High reach and heavy load capacity, automating the most demanding forklift jobs. |

Collaborative Palletizing Arms: While not mobile, stationary robotic arms are a crucial part of the pallet handling ecosystem. They automate the loading/unloading of items onto the pallet itself. Increasingly, these "cobots" work in tandem with mobile pallet handling robots for a fully automated pack-out to storage workflow.

Key Benefits and ROI of Implementing Pallet Handling Robots

The shift to automated pallet handling is driven by compelling, quantifiable advantages that address core business challenges.

-

Dramatic Gains in Operational Efficiency & Throughput: Robots work consistently 24/7 without breaks, maintaining optimal speed. Their routes are optimized by software to eliminate empty travel and congestion. This leads to a higher, more predictable flow of goods. As referenced in competitive materials, intelligent multi-robot scheduling can increase handling efficiency increased by 40%, directly translating to faster order fulfillment and increased storage throughput.

-

Enhanced Workplace Safety: Removing manual forklifts from areas with pedestrian traffic eliminates a major source of serious warehouse accidents. Pallet handling robots are equipped with multi-layer safety systems—LiDAR, 3D cameras, and bumpers—that ensure they stop or maneuver safely around people and unexpected obstacles.

-

Labor Optimization and Strategic Resource Allocation: In a tight labor market, robots provide stability. They take over repetitive, physically demanding transport tasks, allowing your existing workforce to be upskilled for higher-value roles like quality control, system management, or complex problem-solving. This improves both job satisfaction and operational resilience.

-

Unparalleled Accuracy and Traceability: Automated systems follow digital instructions precisely, drastically reducing errors like misplaced pallets or incorrect staging. Every movement is logged, providing complete traceability for each pallet from receipt to shipping. This is critical in regulated industries like pharmaceuticals and food, where "zero-error sterile handling" and compliance with GMP standards are non-negotiable.

-

Scalability and Future-Proofing: Scaling an AMR fleet is often as simple as deploying additional units and updating the software. This modularity allows you to start with a pilot in one area (e.g., replenishment) and expand seamlessly to others (e.g., shipping sortation) as needed, aligning investment with growth.

Understanding the ROI: The Return on Investment is calculated by weighing the above benefits against costs. Key factors include:

-

Cost Avoidance: Reduced labor costs associated with shifts, overtime, and turnover.

-

Productivity Gains: Increased throughput and capacity without expanding floor space.

-

Error Reduction: Savings from less product damage, fewer shipping errors, and lower inventory shrinkage.

-

Safety Savings: Lower insurance premiums and costs associated with workplace accidents.

How to Integrate Pallet Handling Robots into Your Warehouse: A Step-by-Step Guide

Successful integration is a strategic project, not just a purchase. Here is a practical checklist to ensure a smooth deployment.

Step 1: Process Assessment & Goal Setting

Identify the "pain point" processes. Are you targeting receiving, storage put-away, line replenishment, or order picking? Define clear, measurable goals (e.g., "Reduce pallet moves from receiving to storage from 2 hours to 30 minutes").

Step 2: Environment & Data Readiness Audit

-

Physical: Assess flooring condition, aisle widths, dock heights, and charging infrastructure.

-

Digital: This is critical. The " WMS/MES integration protocols and safety certification systems" noted as a knowledge barrier is key. Ensure your WMS can communicate task lists via API. Clean, digital master data (pallet dimensions, storage locations) is essential.

Step 3: Choosing the Right Technology & Partner

Match the robot type from the table above to your needs. Vendor selection is crucial. Look beyond hardware to their software's power, industry-specific experience (e.g., solutions for automotive's "last 100 meters" or semiconductor's cleanroom requirements), and local support capabilities in your target region, such as Germany.

Step 4: Pilot Deployment

Start with a limited scope, such as automating pallet movement for one production line or within a single storage zone. This phase is for testing, gathering data, building internal confidence, and refining workflows before full commitment.

Step 5: Full-Scale Implementation & Change Management

Roll out in phases. Develop comprehensive training programs for operators, maintenance staff, and managers. Foster a culture of collaboration between your team and the new robotic workforce.

The Future of Pallet Handling: Smarter, More Integrated, and More Adaptive

The evolution is rapid. Future pallet handling robots will be powered by deeper AI and Machine Learning, enabling predictive analytics (anticipating bottlenecks) and more adaptive behaviors. Advanced vision systems will allow for handling non-standard pallet stacks and performing basic quality checks on the go. We will also see tighter ecosystem integration, moving towards plug-and-play compatibility with other automation systems (conveyors, AS/RS, sorters) for a truly seamless "lights-out" logistics pipeline.

Conclusion

Pallet handling robots are no longer a futuristic concept but a present-day solution for building a more efficient, safe, and resilient logistics operation. From the flexible AMR to the robust robotic forklift, the technology offers a path to address labor challenges, skyrocketing consumer expectations, and the relentless pressure on margins.

The journey begins with understanding your own processes and choosing a partner whose technology and expertise align with your specific industry challenges and ambitions. By automating the fundamental movement of pallets, you unlock the potential of your entire supply chain, laying a smart foundation for the future of your warehouse.

Previous : Electronics Factory Handling Robots: 5 Key Applications for 2026

Next : Humanoid Service Robots: Applications in Healthcare and Hospitality

Back

to List

to List

Popular News

-

2026-01-28

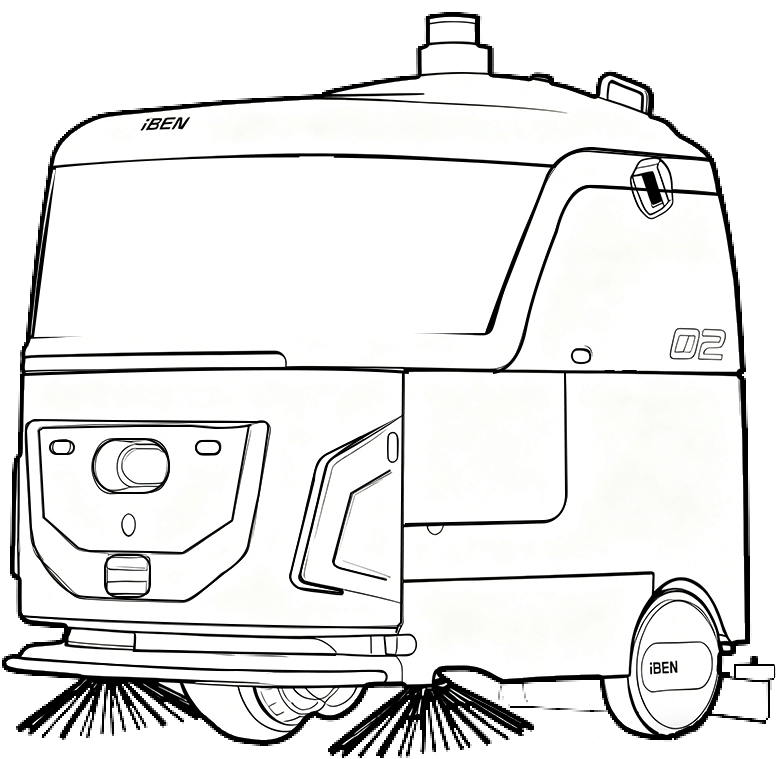

Automatic Cleaning Robots for Smart Factories and Warehouses: Technology and Intelligent Solutions

-

2026-01-28

The Rise of Service Robot Manufacturing: Key Technologies and Market Leaders

-

2026-01-28

2026 Material Handling Robot Trends: Balancing Flexibility & ROI

-

2026-01-28

Electronics Factory Handling Robots: 5 Key Applications for 2026

-

2026-01-26

Humanoid Service Robots: Applications in Healthcare and Hospitality